| |

HIDE DETAILS |

|

Full Penetration Ram (5" from compression wall) is standard on every model to fully compress material with every stroke which substantially increases bale density in any particular force package. Partial bales are also achievable with the full penetration feature. |

|

Laser Positioner for compression ram, ejector ram, and NexDoor® for accurate positioning indication. This is a precise, dependable and safe method of acknowledging ram movement and position. It also eliminates the need for a sprocketed counter wheel. |

|

NexDoor® Bale Door is a standard component that serves as a multi-purpose bale door used as a bale separator, clamp for plugged bale mode, oversized bale release, and allows for variable bale dimensions. |

|

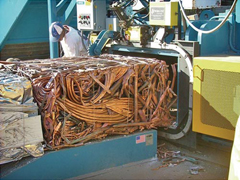

Galaxy2R Series Balers can easily switch processing modes. They can handle a variety of recyclable materials such as copper, aluminum cans, OCC, solid waste, PET and much more. |

|

Shear Blade is replaceable and reversible. |

|

Serrated Body Shear Blade – V-angled shape forces material to the center of the blade and they are adjustable and replaceable. |

| Step Liners – replaceable tongue & groove floor and ram liners provide superior wear resistance. They keep material from getting under the ram and train the wear to the more easily replaced liners – floor strips are 500 brinnel steel and the ram bottom strips are 400 brinnel. |

|

Adjustable Shear Beam - The body shear blades are adjustable from the exterior of the machine for a much easier and safer way to keep blades in tolerance without using shims. |

|

Ram Hold Downs – easier and safer way to make adjustments from the outside of the machine. |

|

Understructure – heavy channel and plate construction provides superior strength and durability during high force, high speed baling processes. |

|

Full Eject – Eject ram fully ejects bales which minimizes contamination especially when a partial bale is made. |

|

Maestro® Color Touch-Screen – Menu driven, programmable controller features automatic and manual controls, diagnostics, commodity set-up and troubleshooting functions. |

|

Combination Piston / Vane Pump Hydraulic System – Provides greater horsepower efficiency and more speed while compressing.

Redundant Power Pack – dual motor machines are fully functional when only one motor/pump set is running.

Separate Cooling and Tier Circuit – cools oil even when the machine is off and does not take oil flow away from the main compression.

Remote Skid Mounted Power Pack – can be placed at customer's discretion within 10 ft. of the machine. |

|

Infrared Upper & Lower Actuators - upper infrareds are located on the access door and are adjustable the entire height of the feed hopper. |

|

Stamper - Optional stamper automatically clears shear jams. |

| |

HIDE DETAILS |